Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

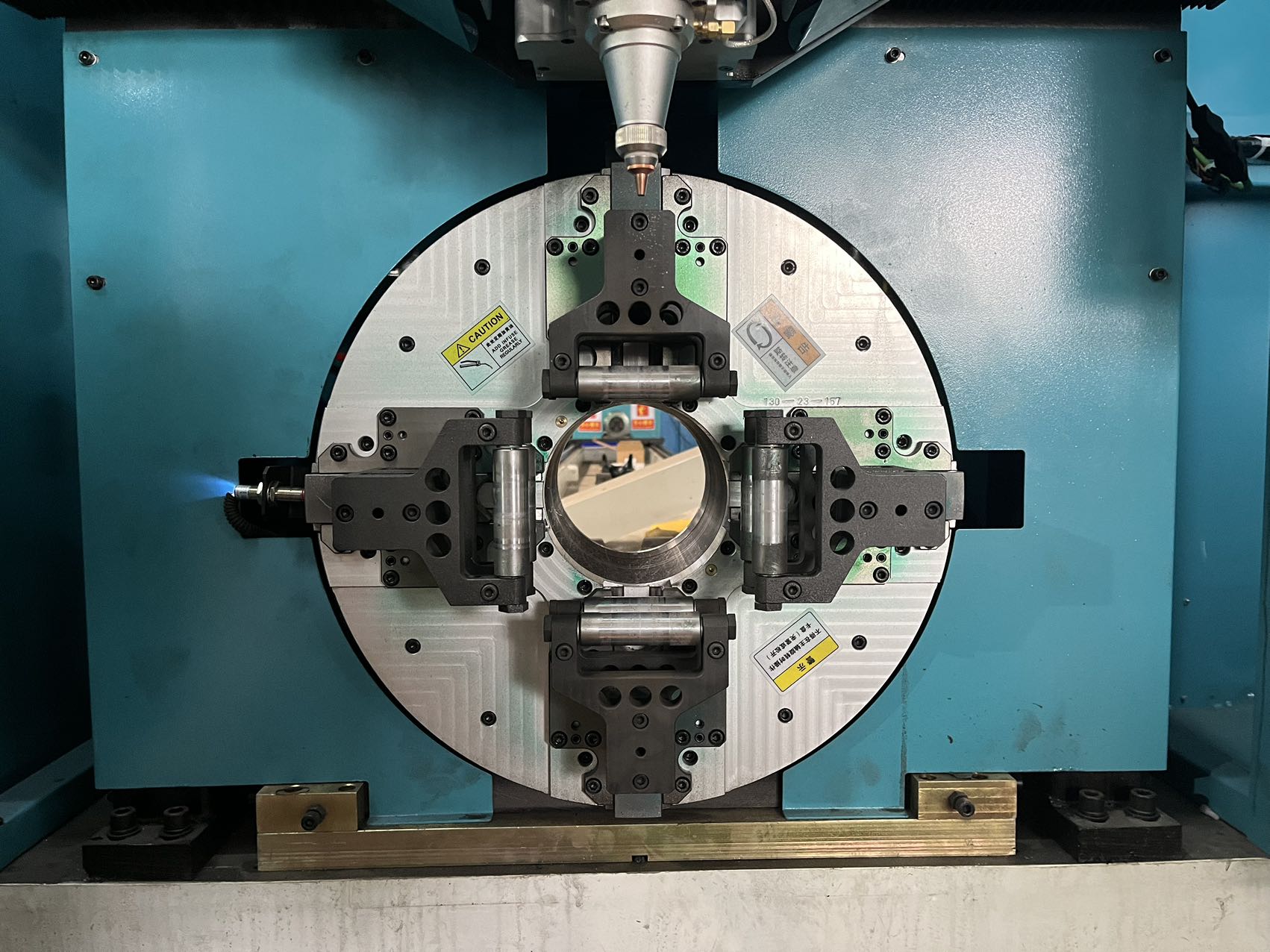

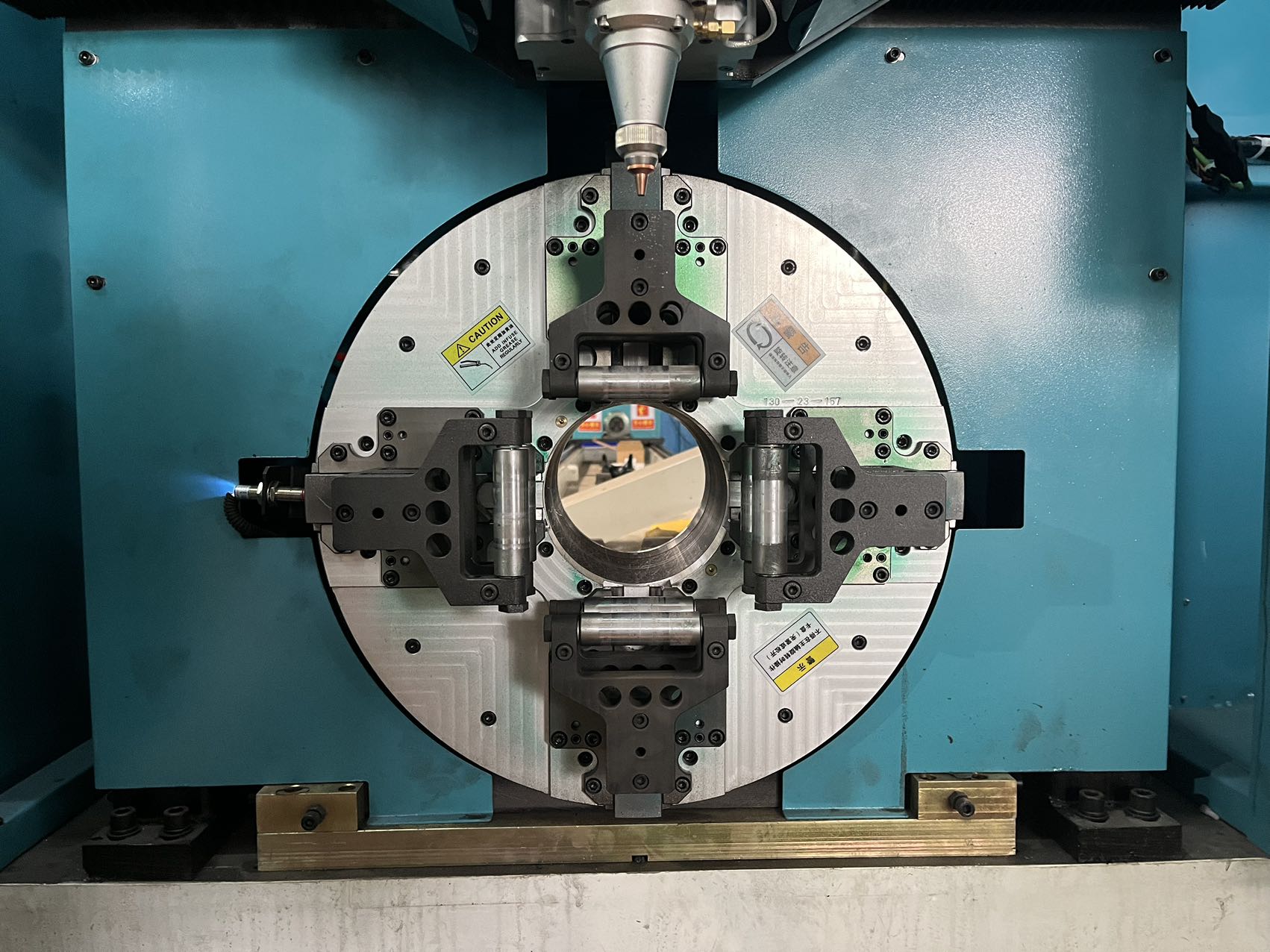

Exploring the World of Laser Cutting: Inside a 300mm Dia Round Pipe Laser Cutting Machine Factory

In the ever-evolving world of manufacturing, technology plays a pivotal role. It ensures that industries stay ahead of the curve. One such technology is laser cutting. It has transformed the way pipes are cut and shaped. Today, we’re going to take a deep dive into the fascinating world of laser cutting. We’ll focus on the incredible machinery used for cutting pipes. Specifically, we’ll discuss the 300mm dia round pipe laser cutting machine.

What is Laser Cutting?

Before we jump into the specifics of the 300mm dia round pipe laser cutting machine, let’s first understand what laser cutting is. Laser cutting is a technology. It uses a laser to cut materials like metal, plastic, or wood. The laser cuts with extreme precision. The laser beam melts, burns, or vaporizes the material along the cut path. This makes it incredibly accurate and efficient. This method is especially useful in industries. It’s essential where precision and intricate designs are required. Laser cutting has been widely adopted in various industries. From aerospace to automotive. It’s now a critical tool in metal fabrication. The precision offered by laser cutting allows manufacturers to produce components. These have tight tolerances, complex geometries, and high-quality finishes. As technology advances, more specialized machines are emerging. They cater to specific needs. One such machine is the 300mm dia round pipe laser cutting machine.

The Importance of Pipe Cutting in Manufacturing

Pipes are an essential part of many industries. These range from plumbing to industrial equipment. Whether it's for transporting gas, liquids, or for structural purposes, pipes need to be cut accurately. Proper cutting ensures the right fit and function. Traditional methods of cutting pipes include using saws or mechanical cutters. These can often be imprecise. This leads to wastage and additional time spent on adjustments. Laser cutting provides a more efficient and accurate solution. It eliminates the need for further processing after the cut. Laser cutting results in smoother edges and more consistent cuts. This is where the 300mm dia round pipe laser cutting machine shines.

What is a 300mm Dia Round Pipe Laser Cutting Machine?

A 300mm dia round pipe laser cutting machine is a specialized laser cutting machine. It’s designed specifically for cutting round pipes. The diameter of these pipes is up to 300mm. This machine is especially useful for industries dealing with metal pipes. These include construction, manufacturing, automotive, and energy. The laser cutting machine offers several advantages over traditional cutting methods.

- Precision and Accuracy: The laser cutting machine can make highly accurate cuts. It cuts along the pipe’s length. This ensures each piece meets the required specifications. This level of precision is especially important when working with pipes that need to fit into complex assemblies or systems.

- Speed: Laser cutting is significantly faster than traditional cutting methods. The machine can cut through pipes of various materials quickly and efficiently. This can improve overall production speed.

- Minimal Material Waste: Laser cutting produces minimal waste. It only removes the material along the cutting path. This is especially beneficial when working with expensive materials like stainless steel, copper, or aluminum.

- Complex Shapes and Patterns: Laser cutters are capable of cutting complex patterns into pipes. Examples include holes, slots, or intricate designs. This is ideal for industries needing customized pipe fittings or unique structural elements.

- Clean Edges: Laser cutting leaves smooth, clean edges on the pipe. This eliminates the need for additional deburring or finishing processes.

How Does a 300mm Dia Round Pipe Laser Cutting Machine Work?

A 300mm dia round pipe laser cutting machine operates by focusing a high-powered laser beam onto the surface of a pipe. The laser beam is typically generated by a CO2 or fiber laser. Both of these are capable of delivering the energy needed to cut through metal.

- Laser Beam Generation: The laser cutter uses either a CO2 or fiber laser source. It generates a high-intensity beam of light. The laser is then directed towards the pipe. This happens through a series of mirrors and lenses. The beam is focused to a precise point.

- Cutting Process: As the focused laser beam strikes the surface of the pipe, it heats the material to its melting point. A jet of gas is directed alongside the laser beam. This is usually nitrogen or oxygen. It blows away the molten material, creating a clean and precise cut.

- Pipe Rotation and Movement: One key feature of a round pipe laser cutting machine is its ability to rotate the pipe during the cutting process. This allows the laser to cut all the way around the pipe. It creates continuous cuts without the need for repositioning.

- Control System: The entire process is controlled by a computer numerical control (CNC) system. This system allows operators to program the machine. They can cut specific shapes, sizes, or patterns on the pipe. The CNC system ensures every cut is executed precisely according to specifications.

- Cooling: The laser cutting process generates significant heat. A cooling system is used to prevent overheating of the laser and the pipe. This ensures the machine operates efficiently. The material remains unaffected by excess heat.

Applications of a 300mm Dia Round Pipe Laser Cutting Machine

The 300mm dia round pipe laser cutting machine is used in various industries for different purposes. Here are some of the key applications:

- Construction Industry: In construction, pipes are used for various purposes. These include water and gas distribution, structural support, and ventilation. The ability to cut pipes accurately ensures they fit perfectly into building systems. The 300mm dia round pipe laser cutting machine is especially useful for cutting steel pipes. Steel pipes are often used in large-scale construction projects.

- Automotive Industry: The automotive industry uses pipes for exhaust systems, fuel lines, and other components. Laser cutting machines are ideal for making precise cuts on pipes used in vehicles. They allow manufacturers to create parts that fit together seamlessly.

- Energy Sector: In the energy sector, pipes are essential for transporting oil, gas, and water across vast distances. The 300mm dia round pipe laser cutting machine ensures the pipes used in energy production and distribution are cut accurately. This reduces the risk of leaks or other issues from imprecise cuts.

- Shipbuilding: Shipbuilders often use large pipes for systems like ventilation, plumbing, and exhaust. Laser cutting machines allow shipbuilders to cut these pipes with precision. This ensures the pipes are ready for assembly without additional work.

- Furniture and Decorative Items: Surprisingly, laser cutting machines are also used for creating decorative elements for furniture and home décor. The precision offered by the 300mm dia round pipe laser cutting machine can be used to create custom designs. These include furniture frames, lighting fixtures, and art installations.

Advantages of Working with a 300mm Dia Round Pipe Laser Cutting Machine Factory

Working with a factory that specializes in 300mm dia round pipe laser cutting machines offers many advantages. These factories have the expertise and equipment to deliver high-quality, precise cuts every time. Some benefits include:

- Expertise and Experience: Factories specializing in laser cutting have skilled technicians. They understand the intricacies of the technology. They can deliver top-notch results.

- Customization: A factory specializing in laser cutting can provide custom solutions. These are tailored to your specific needs. Whether you need specialized pipe fittings or unique designs, they can deliver exactly what you need.

- Quality Assurance: Reputable laser cutting factories implement strict quality control measures. This ensures every pipe cut meets the required standards. This reduces defects or errors in your final product.

- Cost-Effectiveness: While the initial investment in laser cutting technology can be high, working with a specialized factory can be cost-effective in the long run. The speed, precision, and minimal waste associated with laser cutting help reduce overall production costs.

- Faster Turnaround Times: Since laser cutting is faster than traditional cutting methods, factories can offer quicker turnaround times. This allows businesses to meet tight deadlines.

Conclusion

Laser cutting technology has revolutionized the manufacturing process. This is particularly true for industries dealing with metal pipes. The 300mm dia round pipe laser cutting machine offers unmatched precision, speed, and efficiency compared to traditional cutting methods. Whether it’s for construction, automotive, energy, or other industries, this specialized machine ensures that pipes are cut to perfection.

By understanding how these machines work and the benefits they offer, businesses can make more informed decisions about their manufacturing processes. For anyone needing high-quality, precise pipe cutting, a 300mm dia round pipe laser cutting machine factory is a great place to start!