Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

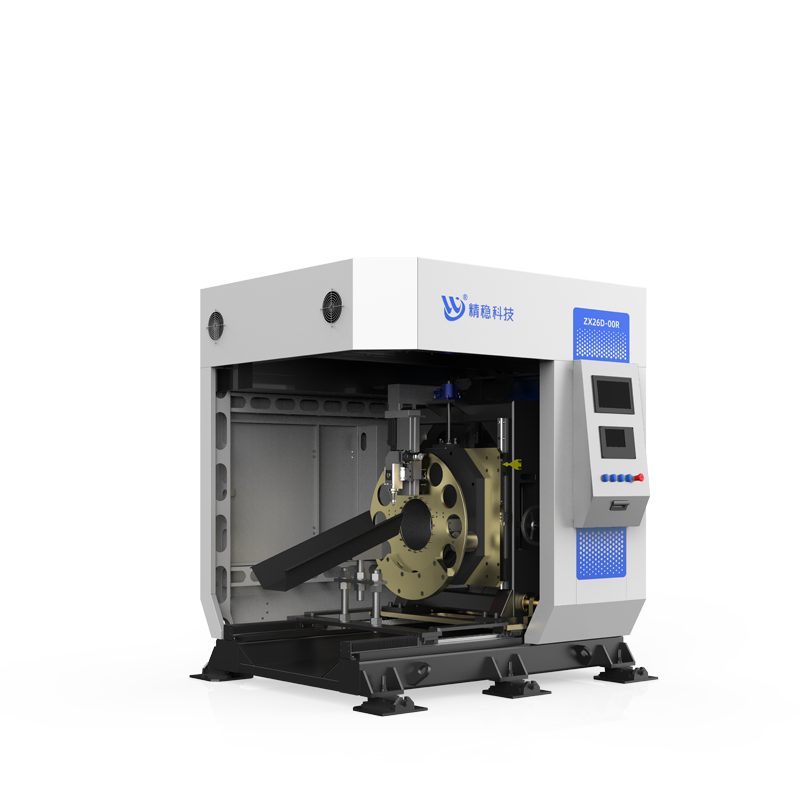

1-100mm Thick Metal Sheet Laser Machine

In modern metal fabrication industries, versatility and precision are key factors that determine productivity and competitiveness. Handling a wide range of metal sheet thicknesses requires advanced machinery capable of maintaining accuracy without compromising speed. 1-100mm thick metal sheet laser machine manufacturers, like Jingwen, provide cutting-edge solutions for industrial buyers seeking reliable, high-performance equipment that meets diverse manufacturing needs.

The Need for Versatile Laser Cutting Solutions

Metal fabrication spans numerous sectors, from automotive and construction to heavy machinery and shipbuilding. Each sector demands different material thicknesses, ranging from thin sheets of 1mm to thick plates of 100mm. Traditional cutting methods, such as plasma or waterjet cutting, struggle to maintain precision across such a broad range. This gap has created a strong demand for specialized 1-100mm thick metal sheet laser machines capable of:

-

Handling varying steel and metal sheet thicknesses efficiently

-

Maintaining clean, precise edges regardless of thickness

-

Reducing material waste and minimizing production costs

Manufacturers like Jingwen specialize in producing high-quality laser cutting machines that meet these requirements, ensuring B2B clients can operate efficiently across multiple applications.

Technical Advantages of 1-100mm Thick Metal Sheet Laser Machines

Advanced laser cutting technology allows for precise cuts on sheets ranging from 1mm to 100mm. Key features offered by Jingwen include:

-

High Laser Power

To cut thick sheets efficiently, high-power lasers ensure smooth edges without warping or heat damage. -

CNC Precision Control

Sophisticated CNC systems allow precise programming for complex geometries and repeatable accuracy. -

Adjustable Cutting Speed

Cutting parameters can be optimized based on material type and thickness, ensuring consistent quality. -

Minimal Heat-Affected Zone

Laser cutting reduces thermal distortion, critical for maintaining sheet integrity and reducing post-processing. -

Automation and Integration

Automated loading, unloading, and material handling reduce labor costs and improve throughput.

By incorporating these features, Jingwen ensures that B2B buyers receive machines that maximize both productivity and quality across a wide range of sheet thicknesses.

Applications Across Industries

1-100mm thick metal sheet laser machines are essential in multiple industries, offering unmatched versatility:

-

Automotive Industry: Cutting structural steel components and panels of varying thicknesses with precision.

-

Construction & Architecture: Fabricating steel frameworks, building panels, and decorative elements.

-

Heavy Machinery Manufacturing: Producing durable components from thick steel sheets, such as frames and machinery bases.

-

Shipbuilding: Handling thick plates required for ship hulls, decks, and internal reinforcements.

-

Appliances & Furniture: Producing metal parts for industrial appliances and commercial furniture.

Jingwen machines excel in all these applications, providing a single solution for businesses that need flexibility across thin and thick metal sheets.

Why Choose Jingwen for Your Laser Cutting Needs

Selecting the right manufacturer is critical for B2B buyers looking for reliable performance, durability, and support. Jingwen stands out among 1-100mm thick metal sheet laser machine factories due to:

-

Extensive Manufacturing Expertise

Decades of experience in laser machine manufacturing ensures consistent quality and durability. -

Customizable Options

From laser power to table size and automation level, Jingwen offers solutions tailored to the client’s specific production requirements. -

Comprehensive After-Sales Service

Installation, operator training, maintenance support, and spare parts availability ensure uninterrupted production. -

Global Reach

With a strong international presence, Jingwen can deliver and support machines in major industrial regions worldwide. -

Cost-Effective Solutions

Competitive pricing without compromising quality makes Jingwen a preferred choice for industrial procurement.

Operational Benefits for B2B Buyers

Businesses investing in 1-100mm thick metal sheet laser machines gain multiple operational advantages:

-

Reduced Production Time: High cutting speeds and automation enable faster completion of large orders.

-

Lower Material Waste: Precise cutting minimizes scrap, reducing raw material costs.

-

High Repeatability: CNC control ensures identical cuts across high-volume production runs.

-

Versatility: One machine handles both thin and thick sheets, reducing the need for multiple machines.

-

Energy Efficiency: Modern laser technology consumes less power relative to traditional cutting methods.

These benefits translate directly into cost savings, higher productivity, and improved competitiveness for B2B buyers.

Selecting the Right Machine for Your Business

When choosing among 1-100mm thick metal sheet laser machine factories, B2B buyers should consider:

-

Material Compatibility: Ensure the machine handles the metals and alloys used in your operations.

-

Cutting Capacity: Verify the machine can process your typical sheet sizes and thicknesses.

-

Automation Level: Higher automation improves efficiency and reduces labor costs.

-

Maintenance and Support: Choose manufacturers like Jingwen that provide reliable after-sales service.

-

Return on Investment: Evaluate total costs, including energy, maintenance, and productivity gains.

By considering these factors, buyers can select a solution that meets production demands while optimizing operational efficiency.

Case Studies and Success Stories

Industrial clients who have adopted Jingwen’s 1-100mm thick metal sheet laser machines report significant improvements:

-

Increased production efficiency by 25–40%

-

Reduced material wastage by 15–20%

-

Enhanced ability to cut complex shapes in thick and thin sheets

-

Reliable performance with minimal downtime

These success stories demonstrate the practical value of investing in high-quality machines from trusted 1-100mm thick metal sheet laser machine factories like Jingwen.