Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

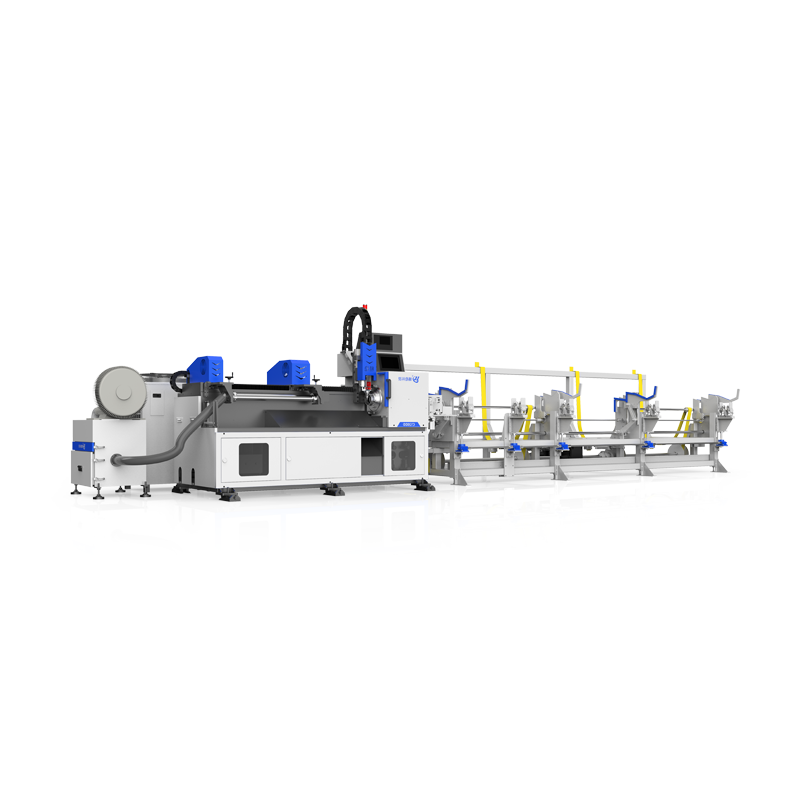

300mm Dia Round Pipe Laser Cutting Machine Factory – Precision Solutions by Jingwen

In modern industrial manufacturing, the demand for precise, efficient, and versatile pipe processing has grown significantly. From automotive exhaust systems to structural steel frameworks, round pipes require accurate cutting to ensure assembly quality and structural integrity. 300mm dia round pipe laser cutting machine factories, such as Jingwen, provide high-performance solutions tailored for B2B buyers seeking reliable, efficient, and precise laser cutting technology.

The Growing Importance of Pipe Laser Cutting

Round pipes are widely used in multiple industries including construction, automotive, furniture, and machinery. Traditional mechanical cutting methods, such as saws or plasma cutting, often face challenges such as:

-

Inconsistent edge quality

-

Warping or deformation

-

High material waste

-

Slow production speeds

The introduction of specialized 300mm dia round pipe laser cutting machines addresses these issues by offering high-speed, high-precision cutting suitable for pipes with diameters up to 300mm. Manufacturers like Jingwen have optimized these machines for industrial efficiency, helping B2B buyers achieve superior quality and operational productivity.

Technical Advantages of 300mm Round Pipe Laser Cutting Machines

Jingwen’s 300mm dia round pipe laser cutting machines feature advanced technologies designed to meet the needs of industrial pipe processing:

-

High-Precision Laser Cutting

Ensures accurate, clean cuts with minimal heat-affected zones, preserving pipe integrity. -

CNC-Controlled Operations

Programmable CNC systems enable precise cutting for complex patterns, consistent quality, and repeatability. -

Automatic Pipe Feeding and Clamping

Reduces manual labor, increases production efficiency, and minimizes positioning errors. -

Versatile Pipe Compatibility

Supports various metal materials, including steel, stainless steel, aluminum, and alloys. -

Optimized Cutting Parameters

Adjustable laser power, cutting speed, and gas pressure allow customization for different pipe thicknesses and materials. -

User-Friendly Interface

Intuitive control systems simplify programming, reducing operator training time and operational errors.

These features position Jingwen as a leading choice among 300mm dia round pipe laser cutting machine factories, delivering solutions that meet demanding industrial standards.

Applications Across Industries

The 300mm dia round pipe laser cutting machines from Jingwen are highly versatile and applicable across several sectors:

-

Automotive Industry: Precision cutting of exhaust pipes, chassis components, and structural tubing.

-

Construction: Steel frameworks, scaffolding, and structural pipelines requiring accurate dimensions.

-

Furniture Manufacturing: Cutting metal tubes for chairs, tables, and furniture frameworks.

-

Machinery & Equipment: Pipe-based components for industrial machinery, conveyors, and heavy equipment.

-

Aerospace & Transportation: Precision-cut piping for aircraft, rail vehicles, and specialized vehicles.

By investing in Jingwen machines, B2B buyers can reliably process a wide variety of pipes while maintaining high quality and efficiency.

Why Choose Jingwen Among Pipe Laser Cutting Machine Factories

Selecting the right manufacturer is crucial for industrial buyers seeking precision, reliability, and long-term support. Jingwen stands out among 300mm dia round pipe laser cutting machine factories due to:

-

Decades of Industry Experience

Jingwen’s expertise ensures high-quality, durable, and reliable laser cutting machines. -

Customizable Solutions

Options for laser power, pipe diameter range, table size, and automation features meet diverse production needs. -

Comprehensive After-Sales Support

Installation, operator training, technical support, and maintenance services reduce downtime and enhance productivity. -

Global Presence

Timely delivery and local support in key industrial regions worldwide. -

Competitive Pricing

High-performance machines at cost-effective prices provide excellent ROI for B2B buyers.

Operational Advantages for B2B Buyers

B2B clients using Jingwen’s 300mm dia round pipe laser cutting machines enjoy multiple operational benefits:

-

High Productivity: Automated feeding and CNC control allow high-volume pipe cutting with minimal downtime.

-

Reduced Material Waste: Clean cuts minimize scrap and reduce raw material costs.

-

Consistent Quality: Every pipe is cut to exact specifications, ensuring precise assembly.

-

Flexibility: Capable of cutting various pipe diameters and thicknesses without additional equipment.

-

Lower Labor Costs: Automation reduces manual handling and the risk of errors.

These operational advantages directly translate into higher production efficiency, cost savings, and competitive advantages for industrial buyers.

Selecting the Right 300mm Pipe Laser Cutting Machine

When evaluating 300mm dia round pipe laser cutting machine factories, B2B buyers should consider:

-

Pipe Diameter & Thickness Range: Ensure the machine can handle the required dimensions.

-

Material Compatibility: Confirm that it supports steel, stainless steel, aluminum, or other alloys used in production.

-

Automation Features: Automated feeding, clamping, and unloading improve efficiency.

-

Maintenance & After-Sales Support: Reliable technical assistance ensures uninterrupted operation.

-

Return on Investment: Consider productivity gains, labor savings, and reduced material waste when comparing options.

Jingwen provides machines designed to meet these criteria, making it a trusted partner for industrial pipe processing.

Case Studies and Success Stories

Industrial clients who have adopted Jingwen’s 300mm dia round pipe laser cutting machines report significant benefits:

-

Increased production efficiency by 30–40%

-

Reduced material waste and rework

-

Enhanced precision for complex pipe geometries

-

Streamlined workflow and reduced labor requirements

These results demonstrate why Jingwen is a leading choice among 300mm dia round pipe laser cutting machine factories globally.