Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

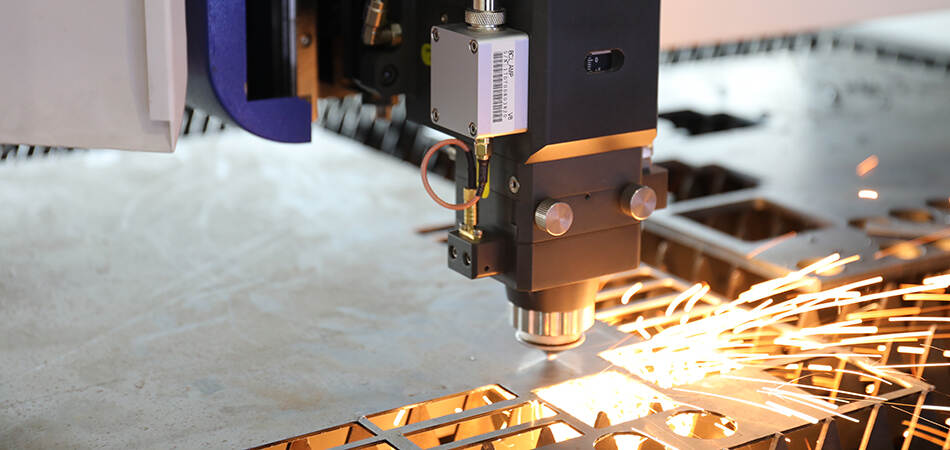

Advantages of Laser Pipe Cutting Machine

With the continuous advancement of industrial automation and manufacturing technology, laser pipe cutting machines, as an efficient and precise cutting tool, are gradually becoming an indispensable production equipment in various industries. Compared with traditional cutting methods, laser pipe cutting machines have the following significant advantages:

- High precision cutting

The laser cutting machine uses high-energy laser beams for cutting, which can achieve extremely high cutting accuracy, usually with an error of ± 0.1mm. This high precision makes the edges of the cut pipe smooth, eliminating the need for additional processing and reducing processing costs.

- High efficiency

The laser pipe cutting machine has the characteristic of fast cutting and can complete complex shape cutting tasks in a very short time. Compared with traditional mechanical cutting, laser cutting has a faster speed, which can significantly improve production efficiency and accelerate product delivery.

- Strong flexibility

Laser cutting machine is suitable for pipes made of various materials, such as stainless steel, aluminum alloy, carbon steel, etc., and can also cut pipes of different diameters and thicknesses. Its high flexibility enables enterprises to quickly respond to market demand and adapt to diverse production tasks.

- Reduce material waste

Laser pipe cutting machines can achieve precise cutting design, reduce cutting gaps, and minimize material waste to the greatest extent possible. This feature not only reduces production costs, but also meets the requirements of modern environmental protection, which helps enterprises achieve sustainable development.

- High degree of automation

Modern laser cutting machines are usually equipped with advanced numerical control systems, which can perform programmed operations and reduce manual involvement. In addition, with the advancement of intelligent technology, many devices can achieve remote monitoring and operation, greatly improving work safety and convenience.

- Low maintenance costs

Compared with traditional mechanical equipment, laser pipe cutting machines have less wear and tear, relatively simple maintenance, and reduce equipment maintenance costs and downtime. The service life of the laser is also very long, further improving the economic efficiency of the equipment.

Conclusion

In summary, laser tube cutting machines are increasingly becoming important equipment in the manufacturing industry due to their excellent precision, high efficiency, and flexibility. Whether used in furniture manufacturing, automotive industry, or construction engineering, the advantages of laser cutting machines have made them occupy an increasingly important position in the market, driving the rapid development of related industries. In the fierce market competition, choosing a laser cutting machine will help enterprises improve production efficiency and product quality, thereby gaining greater competitive advantages in the industry.